Three proof paint (moisture-proof, mildew proof, and salt spray proof) is a protective coating specifically used in the electronics industry, such as coating on printed circuit boards to form a protective film, which is usually only a thin layer (about 30-210) μ m) Used to improve the reliability and service life of electronic products in complex environments. The performance and composition of the three proof paint may vary depending on the actual application environment and requirements.

Three proof paint (moisture-proof, mildew proof, and salt spray proof) is a protective coating specifically used in the electronics industry, such as coating on printed circuit boards to form a protective film, which is usually only a thin layer (about 30-210) μ m) Used to improve the reliability and service life of electronic products in complex environments. The performance and composition of the three proof paint may vary depending on the actual application environment and requirements.

Moisture proof performance: The three proof paint can effectively prevent moisture penetration, reduce the dew point on the surface of the circuit board, and thus improve the insulation performance of the circuit board. In some extreme humidity environments, three proof paint can protect circuit boards from condensation and extend their lifespan.

Anti mold performance: Mold is prone to growth and reproduction in humid environments, leading to problems such as corrosion and short circuits on circuit boards. Three proof paint can form a protective film to isolate moisture and inhibit the growth of mold. The experiment showed that the mold rate of the circuit board decreased by about 80% after using the three proof paint.

Salt spray resistance: In high salt spray environments such as the ocean or coastal areas, salt can cause corrosion to circuit boards. Three proof paint has good salt spray corrosion resistance, which can effectively protect circuit boards from corrosion damage. Research has shown that the salt spray test pass rate of circuit boards using three proof paint has increased by about 90%.

Chemical resistance: The three proof paint also has excellent chemical corrosion resistance, which can resist the erosion of various chemical substances, such as acids, alkalis, solvents, etc. This makes the three proof paint suitable for electronic equipment protection in industries such as chemical and petroleum.

Electrical insulation performance: After the curing of the three proof paint, a layer of insulation film is formed, which can effectively prevent current leakage and improve the electrical safety of the circuit board. The experimental data shows that the insulation resistance value of the circuit board can be increased by about 30% after using the three proof paint.

Environmental performance: Some high-quality three proof paints use environmentally friendly solvents and low VOC (volatile organic compounds) formulas, which are harmless to human health and the environment. This has made the three proof paint widely used in the electronics industry.

In summary, the three proof paint has broad application prospects in the electronics industry. By using three proof paint, the reliability and service life of electronic products in harsh environments can be improved, and the failure rate and maintenance cost can be reduced.

Three proof paint is a special formula coating mainly used to protect circuit boards and related equipment from environmental erosion. According to different classification standards, three proof paints can be divided into various types. The following are commonly used three proof paints and their characteristics classified by composition and curing method:

Acrylic ester three proof paint:

Solvent containing acrylic resin three proof paint is currently the most widely used and popular product in the market.

It has the characteristics of dry surface, fast curing time, good three proofing properties, low price, transparent color, flexible texture, and easy repair.

Silicone three proof paint:

Organic silicon three proof paint is a soft and elastic coating material that can effectively release pressure, withstand high temperatures of 200 degrees, and is easy to repair.

Flexible and easy to repair.

Polyurethane three proof paint:

The texture is brittle and has excellent solvent resistance.

In addition to its superior moisture resistance, it also maintains stable performance in low temperature environments.

UV cured three proof paint:

The solvent-free acrylic resin three proof paint adopts UV curing, which can dry the watch in a few seconds to more than ten seconds. The color is transparent, the texture is hard, and it has excellent chemical corrosion resistance and wear resistance.

Organic silicon modified three proof paint:

Taking into account both price and performance, there may also be a cross phenomenon when the above types of three proof paints appear.

Organic silicon modified three proof paint combines the characteristics of acrylic resin three proof paint and organic silicon three proof paint.

Fluorescent three proof paint:

After coating with fluorescent three proof paint, the surface of the coating will be illuminated by a purple light and display blue, which is clear and easy to detect whether the three proof paint is applied properly.

Flexible and easy to repair.

In addition, domestic brands have also developed acrylic triple proof paint, which has a low odor, is environmentally friendly, does not contain aromatic solvents, and operates within the temperature range of -40 ℃ to 130 ℃

The coating materials for conformal coating mainly include three transparent raw materials: Silicone (silicone, silicone), Acrylic (acrylic), Urethane (polyurethane), and some use Epoxy (epoxy resin), but they are unknown materials, so they are less commonly used.

There are two ways to cure the three proof paint: room temperature curing and heat curing.

When applying the three proof paint, the following precautions should be taken:

Preparation before coating: Ensure that the surface to be coated is clean, dry, and free of impurities such as oil, dirt, and oxides. At the same time, operators must wear protective equipment, such as chemical protective goggles, gas masks, and protective gloves, to prevent damage to the skin and eyes caused by the three protective paints.

Control coating amount: Calculate the required amount of coating based on the required area and thickness. During the coating process, it is necessary to control the flow rate of the coating to avoid coating too thick or too thin, which can affect the effectiveness of the three proof paint.

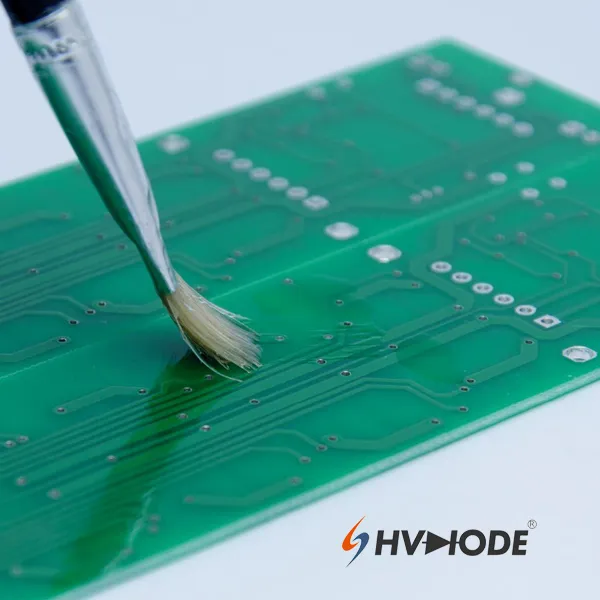

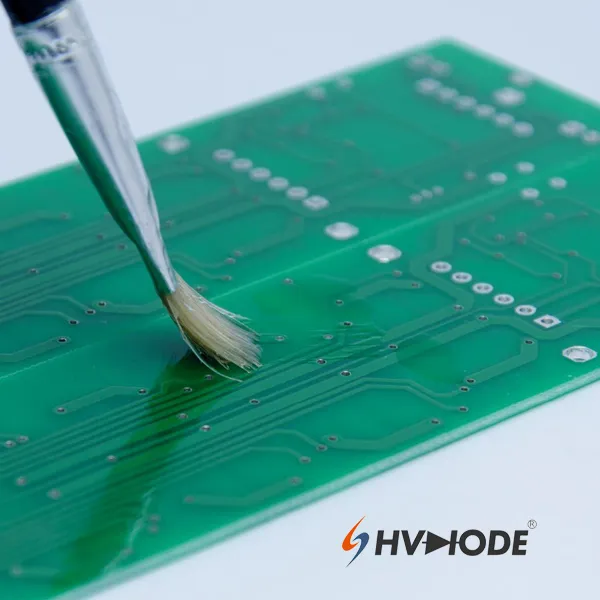

Mastering coating techniques: Using appropriate coating methods such as brushing, spraying, immersion coating, etc. Choose appropriate coating tools such as brushes, sponges, spray guns, etc. based on the surface condition and coating effect requirements. During the coating process, it is necessary to control the flow of the coating to evenly cover the entire surface.

Pay attention to environmental conditions: The application of the three proof paint needs to be carried out under certain temperature and humidity conditions. The temperature should generally be between 20 ℃ -30 ℃, and the relative humidity should be controlled below 50%. If the environmental humidity is too high, the three proof paint is prone to whitening, which affects the quality of the coating.

Pay attention to coating thickness: The coating thickness of the three proof paint should be determined according to specific requirements. Generally speaking, the coating thickness should be controlled between 1-2 mils. An excessively thick coating can cause an increase in internal stress in the paint film, making it prone to cracking and peeling.

Drying and Curing: After coating is completed, wait for the three proof paint to completely dry and cure. The drying and curing time depends on the type of three proof paint used and the temperature and humidity conditions. During the drying process, pollutants such as dust and moisture should be avoided from affecting the coating.

Waste disposal: Used three proof paint and other waste should be properly disposed of in accordance with relevant regulations to prevent pollution to the environment.

By paying attention to the above matters, the coating quality and effect of the three proof paint can be effectively improved, and the performance and service life of electronic devices such as circuit boards can be protected in various harsh environments. At the same time, attention should also be paid to safe operation and environmental protection to ensure safety and sustainable development in the production process.